Description

High Alumina Cement

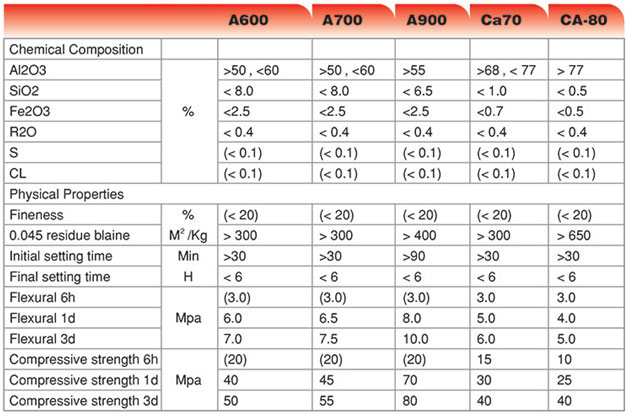

High Alumina Cement is a rapid-hardening cement made by fusing at 1.500 to 1.600 C (2.730 to 2.910 F) a mixture of bauxite and limestone in a reverberatory or electric furnace or in a rotary kiln. It also can be made by sintering at about 1.250 C (2.280 F). Suitable bauxites contain 50 to 60 percent alumina, up to 25 percent iron oxide, not more than 5 percent silica, and 10 to 30 percent water of hydration. The limestone must contain only small amounts of silica and magnesia. The cement contains 35 to 40 percent lime, 40 to 50 percent alumina, up to 15 percent iron oxides , and preferably not more than about 6 percent silica. The principal cementing compound is calcium aluminate (CaO • Al203).

High-alumina cement gains a high proportion of its ultimate strength within 24 hours and has a high resistance to chemical attack . It also can be used in refractory linings for furnaces. A white form of the cement , containing minimal proportions of iron oxide and silica, has outstanding refractory properties.