Description

Semi Coke

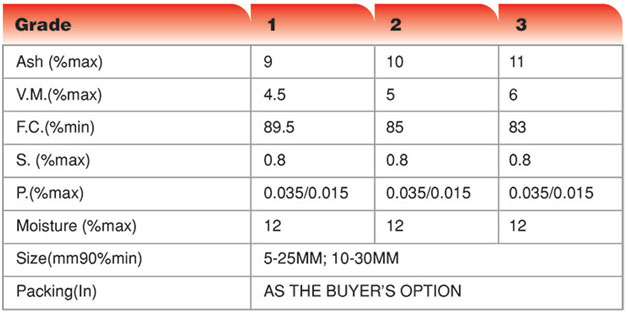

Based on the application, Electric Arc Furnace (EAF) Coke, in contrast with normal blast furnace coke and foundry coke, is unique, which requires lower CSR (Coke Strength after Reaction), higher CRI (Coke Reactivity Index) and proper Electric Resistivity as well. This material has been widely used in the applications for Electric Furnaces in production of Steel, Ferro Alloys, Graphite, Refractories and Fertiliser industries. Coke is also added to steel ladles to re-carburize the melt after discharge from the furnace.